PRODUCT DESCRIPTION

The IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER „TYPE 2“ has been specially developed for the installation of construction elements in the insulation level in front of the load-bearing wall of buildings. The new „TYPE 2“ supplements the tried-and-trusted and comprehensively tested system components of our IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER „TYPE 1“ by further application options. „TYPE 2“ has been especially developed for the installation of small to medium-sized windows and is an ideal supplement to the system family of the IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER.

The IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER „TYPE 2“ is made up of the system components attachment console, spacer plate, insulating profile and system bracket, as well as the system adhesive ISO-TOP FLEXADHESIVE WF (see table of system components). In comparison with the current IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER „TYPE 1“, „TYPE 2“ is mainly characterised by the point absorption of wind pressure and suction loads at the side by means of attachment consoles. The certified aluminium attachment consoles are pre-installed at the usual side attachment points for window installation and then covered with the highly heat-insulating insulating profile and thermally decoupled. The long side of the insulating profile is glued to the surface of the masonry resulting in an all-round air tight insulating frame.

For load transfer, the system bracket is glued to the masonry first using the system adhesive ISO-TOP FLEX-ADHESIVE WF in the lower connection area, and then screwed in place. The air tight and completely thermally decoupled frame around the edge of the whole window area creates an ideal precondition for load transfer and offers an ideal installation level for installation and sealing according to the specifications of the RAL “installation guide”.

PRODUCT ADVANTAGES

- installation of windows of small to medium size in the insulation level

- optimum integration in thermal insulation composite systems

- air tight connection to the masonry

- optimisation of the Ψ-value thanks to highly heat-insulating insulating profiles

- excellent for energy-related building renovation

- complies with EnEV requirements and the recommendations of the RAL “installation guide”

- can be combined with the IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER „TYPE 1“

- 10 year performance guarantee*

*On the conditions of the manufacturer (available upon request).

SYSTEM COMPONENTS

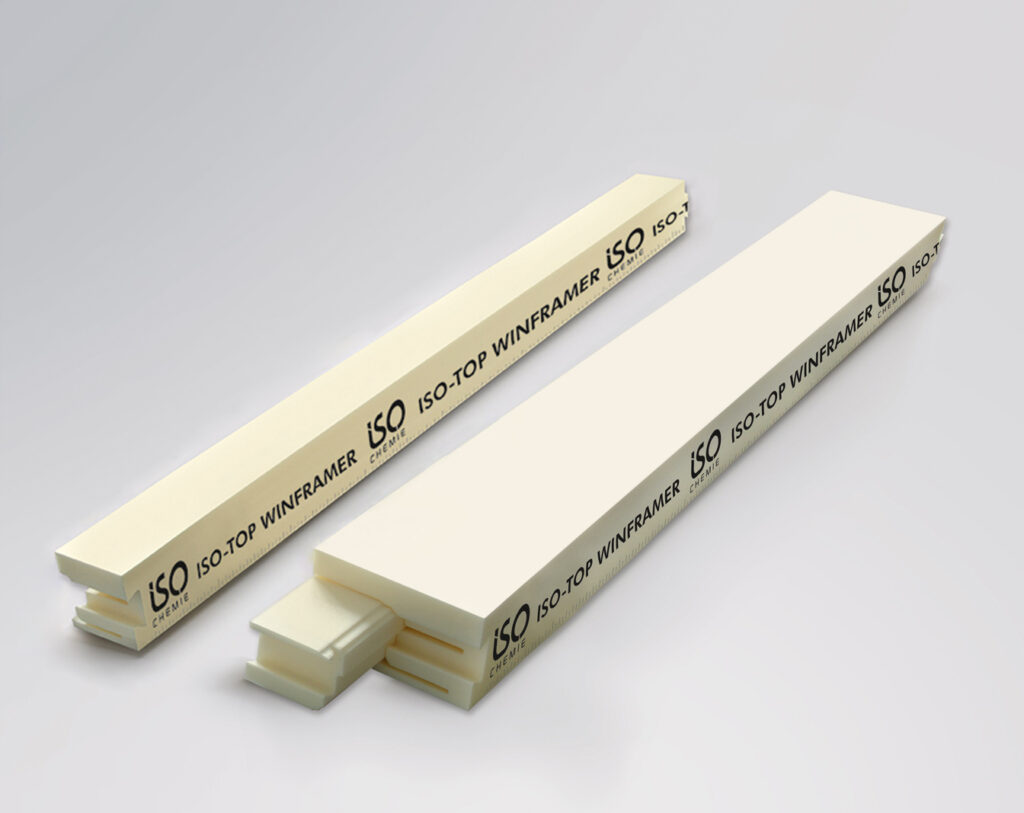

ISO-TOP WINFRAMER INSULATING PROFILE 80 / 80 AND 140 / 80

ISO-TOP WINFRAMER INSULATING PROFILES are available for projections of 80 and 140 mm. With a width of 80 mm and a height of 80 mm, ISO-TOP WINFRAMER INSULATING PROFILES 80 / 80 are excellent for window and door elements which are fitted in the direct transition area between the wall and the EWIS. With this dimension, in front of wall installation can be realised for most of the window and door systems on the market. With a width of 140 mm and a height of 80 mm, the ISO-TOP WINFRAMER INSULATING PROFILES 140 / 80 provide a larger projection. This finish can be used for window and door elements with larger fitting depths, for example, or in combination with roller shutter add-on systems.

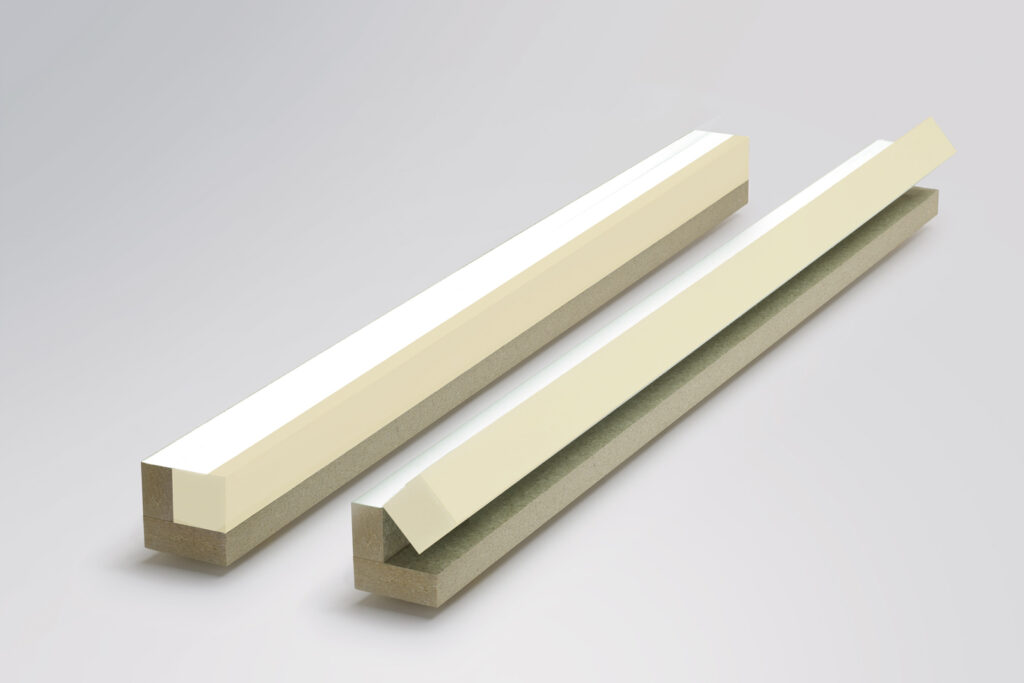

ISO-TOP WINFRAMER SYSTEM BRACKET „TYPE 2“ 80 / 80 AND 140 / 90

ISO-TOP WINFRAMER SYSTEM BRACKETS „TYPE 2“ are particularly suitable for load transfer in the lower connection area of window and door elements with in front of wall installation. These are available in two different sizes to match the insulating profiles. The ISO-TOP WINFRAMER SYSTEM BRACKET „TYPE 2“ 80 / 80 (80 mm height and 80 mm width) is used for classic projections. The dimension 140 / 90 (140 mm width and 90 mm height) is designed for larger projections of up to 140 mm.

ISO-TOP WINFRAMER ATTACHMENT CONSOLES & SPACER PLATE

Attachment consoles comprising a special aluminium bracket combination are provided to fix the windows in place. The tested aluminium attachment consoles are fastened to the masonry at the top and sides using standard, approved facade screws.

SYSTEM ADHESIVE ISO-TOP FLEX-ADHESIVE WF

ISO-TOP FLEX-ADHESIVE WF is a high-quality, neutral cure, single-component, permanently flexible adhesive on a hybrid-polymer basis. It was developed especially for gluing the IN FRONT OF WALL INSTALLATION SYSTEMs ISO-TOP WINFRAMER and makes tension-free structural bonding of the system possible. ISO-TOP FLEX-ADHESIVE WF is also used for sealing and bonding corner connections and can be used on damp surfaces. Refer to the ISO-TOP FLEX-ADHESIVE WF product data sheet for further information.

APPLICATION

The IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER „TYPE 2“ can be used quickly and easily for the installation of windows in the insulation or cavity area. The ISO-TOP WINFRAMER ATTACHMENT CONSOLES are fastened at the top and sides using standard, approved facade screws. The number of attachment points depends on the window to be installed and the loads to be absorbed in this particular case. Then the ISO-TOP WINFRAMER INSULATING PROFILES made of high-compressed XPS polystyrene are fitted snugly over the attachment consoles. These ensure that the individual attachment points are completely covered and thus for optimisation of the Ψ-value in terms of thermal insulation. The insulating profiles are successfully glued to the masonry using ISO-TOP FLEX-ADHESIVE WF. The insulating frame provides the perfect basis for the professional installation of windows using multi-functional joint sealing tapes such as ISO-BLOCO ONE, complying with the principle of a 3-level- sealing set out in the RAL “installation guide”. The IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER „TYPE 2“ is covered directly by the installation of an external wall installation system.

Installation example: IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER „TYPE 2“

Dovetail connection

Dovetail connection

The insulating profiles have a dovetail connection on the end for quick and easy installation. The insulating profiles required are simply fitted together and installed on the wall. This makes handling much easier and provides for a clean and technically perfect connection to the masonry wall.

| Technical data | Standard | Classification |

| ISO-TOP WINFRAMER INSULATING PROFILES and INSULATING CORE “TYPE 2” | ||

| Material description | XPS polystyrene | |

| Building material class | DIN 4102 | B1 |

| Building material class | DIN EN 12667 | λ = 0,036 W/m*K |

| Resistance | usual construction materials, except solvents | |

| ISO-TOP WINFRAMER attachment console | ||

| Material description | high-strength aluminum alloy | |

| Load-bearing capacity according to statical calculation | > 0,45 kN | |

| Execution | 2-part (bearing angle and supporting angle) | |

| Drill hole | diameter 8 mm | |

| Colour | aluminum | |

| Dimension tolerance | DIN 7715 T5 P3 | requirements fulfilled |

| ISO-TOP WINFRAMER SYSTEM BRACKETS “TYPE 2” ja SPACER PLATE | ||

| Material description | PUR composite | |

| Colour | beige | |

| Building material class | DIN EN 13501-1 | E |

| Building material approval | Z-23.11-2014 | |

| Thermal conductivity | DIN EN 12667 | λ = 0,096 W/m*K |

| Sound reduction | depending on the sound insulation class of the construction element / window up to 50 dBA in the joint | |

| Temperature stability range | -50°C to i +100°C | |

| Ageing resistance | resistant to rotting, non-rotting | |

| Humidity resistance | high humidity resistance / resistant to mould and termites | |

| Dimensional stability | high dimensional stability even with natural weathering | |

| Load transfer | 150 kg/m depending on wall substrate and projection | |

| Dimension tolerance | DIN 7715 T5 P3 | requirements fulfilled |

| Shelf life (system brackets, system boards and insulating core) | 2 years |

| System components | IN FRONT OF WALL INSTALLATION ISO-TOP WINFRAMER “TYPE 2” | ||

| Length | Width / height | Installation position | |

| ISO-TOP WINFRAMER INSULATING PROFILE | 1200 mm | 80 / 80 ja 140 / 80 | side, top |

| ISO-TOP WINFRAMER ATTACHMENT CONSOLES (aluminum bracket combination) | – | 2 + 4 mm või 4 + 4 mm | side, top |

| ISO-TOP WINFRAMER SPACER PLATE | – | in connection with insulating profile 140 / 80 mm | side, top |

| ISO-TOP WINFRAMER SYSTEM BRACKET “TYPE 2” | 1200 mm | 80 / 80 ja 140 / 90 mm | bottom |

| ISO-TOP FLEX-ADHESIVE WF | for fixing on the wall and sealing the system joints | ||

Details and information presented in this document are based on the best knowledge available at the time. They are intended for general information purposes, and it is recommended that users conduct their own tests under their specific conditions to ensure the product’s suitability for its intended use. No definitive guarantee or liability can be given regarding the details or the absolute completeness of the information provided in these guidelines. We reserve the right to improve or modify technical specifications and information without prior notice.