ISO-TOP WINFRAMER „TYPE 3“

|

|

|

|

||||

PRODUCT DESCRIPTION |

PRODUCT ADVANTAGES |

|

|

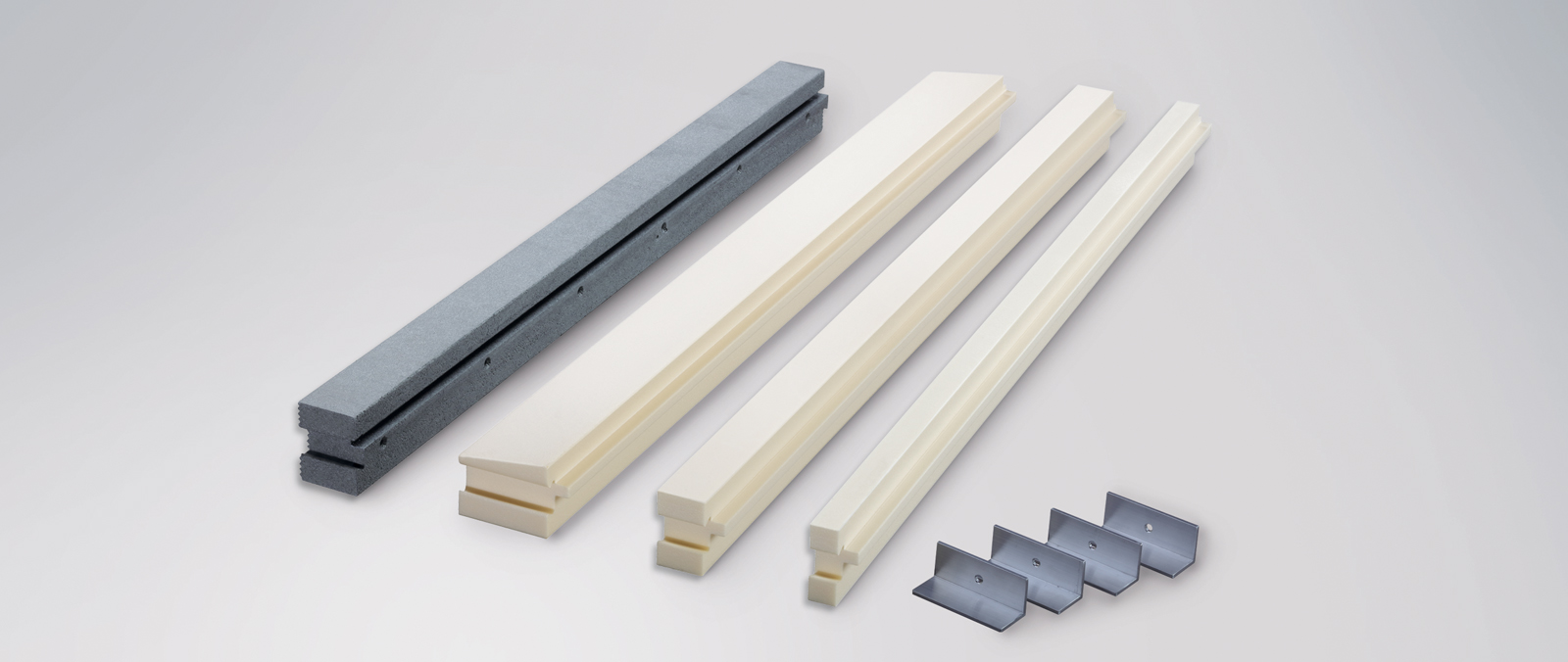

The IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER „TYPE 3“ is made up of load-bearing, thermally insulating B1 system profiles made of high-compressed THERMAPOR. The excellent thermal conductivity of the moulded parts guarantees perfect integration in the EWIS and optimum Ψ-values (Psi). Thus thermal bridges are optimised and a high degree of insulation achieved in the soffit area. This prevents the risk of mould formation in the connection area around the window opening. The IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER „TYPE 3“ provides a high load-bearing capability and load transfer in one. The high density of 150 kg / m3 not only provides a very good load-bearing capacity for bearing window weights, it is also sturdy enough to transfer all other loads safely to the masonry. The ISO-TOP WINFRAMER INSTALLATION FRAMES can be further reinforced using bearing brackets made of aluminium. Tightly fitting console slots have been integrated in the system profiles for this purpose. With large elements in particular, this leaves enough scope for increased loads and fulfilment of the requirements set out in TRAV and the ETB directive. |

|

|

| * On the conditions of the manufacturer (available on request). | ||

APPLICATIONThe IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER „TYPE 3“ can be used for the installation of windows in the insulating layer. The wind suction, dead and casement loads are absorbed directly by the ISO-TOP WINFRAMER INSTALLATION FRAMES and transferred to the load-bearing wall. To achieve this, the ISO-TOP WINFRAMER INSTALLATION FRAMES are glued directly to the masonry using the hybrid polymer-based system adhesive ISO-TOP |

||

| FLEX-ADHESIVE WF and aditionally screwed in place. The mechanical attachment of the window elements is by means of standard window screws. Multi-functional joint sealing tapes or window connection foils from our ISO³-WINDOW SEALING SYSTEM range are ideal for sealing the windows. | ||

|

SUPPLEMENTARY ALUMINIUM CONSOLES*The console slots integrated in the ISO-TOP WINFRAMER SYSTEM PROFILES are designed for the insertion of aluminum consoles for additional stabilization when necessary. For this reason the console slots have been designed so that aluminum consoles can be cut to length from extruded aluminum profiles on the construction site and inserted. Once the aluminum consoles have been clamped tightly in the console slots and thus integrated in the system profiles, they can be fixed together with the system profiles to the masonry within the course of normal installation. This can be an advantage particularly when very large elements are to be installed, very high casement loads occur or other additional requirements are made on structural design or attachment such as e.g. TRAV and ETB. * Available for all dimensions |

| Technical data | Standard | Classification |

| ISO-TOP WINFRAMER SYSTEM PROFILES | ||

| Material description | EPS-F | |

| Colour | silver grey | |

| Building material class | DIN EN 13501-1 | E |

| Bulk density | 150 kg/m³ ± 10% | |

| Flame retardant | HBCD – free flame retardant | |

| UV light stability | at least 6 months direct weathering during the construction phase | |

| Compatibility with adjacent building materials | internal | requirements fulfilled |

| Compatibility with salt water | resistant | |

| Compatibility with hydrochloric acid (10%) | resistant | |

| Compatibility with caustic soda (10%) | resistant | |

| Air permeability coefficient | DIN EN 12114 | a = 0,00 m³/[h*m*(daPa)ⁿ] |

| Thermal conductivity | DIN EN 12667 | λ = 0,040 W/m*K |

| Form stability under thermal load | -40°C to +85°C | |

| Temperature stability range | ISO 75-1 | long term +85°C |

| Ageing resistance | resistant to decay, non-rotting | |

| Bending resistance | DIN EN 12089 | ≥ 650 kPa |

| Shearing stress | DIN EN ISO 14130 | X = 0,217 N / mm² |

| Creep characteristics at 20 % and 60 % | Em = 0.68 0/00 up to 5.2 0/00 | |

| Water absorption (28 days storage) | DIN 12087 | ≤ 1.5 Vol. % |

| Water vapour diffusion resistance μ | DIN EN ISO 12572 | < 500 |

| Waste code | 170604; 170904 | |

| Dimension tolerance | DIN 7715 T5 P3 | requirements fulfiled |

| Shelf life | 2 years | |

| ISO-TOP WINFRAMER INSULATING BARS | ||

| Material description | XPS polystyrene | |

| Colour | light blue | |

| Building material class | DIN 4102 | B1 |

| Thermal conductivity | DIN EN 12667 | λ = 0,034 W/m*K |

| Resistance | usual construction materials, except solvents |

| Type description | Length | Width | Height | Load transfer |

| ISO-TOP WINFRAMER SYSTEM PROFILE 70/80 | 1200 mm | 70 mm | 80 mm | 200 kg/m |

| ISO-TOP WINFRAMER SYSTEM PROFILE 80/80 | 1200 mm | 80 mm | 80 mm | 200 kg/m |

| ISO-TOP WINFRAMER SYSTEM PROFILE 100/80 | 1200 mm | 100 mm | 80 mm | 200 kg/m |

| ISO-TOP WINFRAMER SYSTEM PROFILE 120/80 | 1200 mm | 120 mm | 80 mm | 200 kg/m |

| ISO-TOP WINFRAMER SYSTEM PROFILE 140/80 | 1200 mm | 140 mm | 80 mm | 200 kg/m |

| ISO-TOP WINFRAMER SYSTEM PROFILE 160/80 | 1200 mm | 160 mm | 80 mm | 200 kg/m |

| ISO-TOP WINFRAMER SYSTEM PROFILE 180/80 | 1200 mm | 180 mm | 80 mm | 200 kg/m |

| ISO-TOP WINFRAMER SYSTEM PROFILE 200/80 | 1200 mm | 200 mm | 80 mm | 200 kg/m |

| ISO-TOP WINFRAMER INSULATING BARS | 1200 mm | width/height: 30/80; 50/80 | ||

| ISO-TOP FLEX-ADHESIVE WF | for fixing on the wall and sealing the systemjoints | |||

| ISO-TOP ALUMINIUM CONSOLES | 70/80; 80/80; 100/80; 120/80; 140/80; 160/80; 180/80; 200/80 | |||

| Product Data Sheet |