TRIOTHERM+

Warning: Undefined array key 1 in /data02/virt44898/domeenid/www.ruumala.com/htdocs/wp-content/plugins/gallery-theme/gallery-theme.php on line 96

|  |  |  |

PRODUCT DESCRIPTION | PRODUCT ADVANTAGES | |

TRIOTHERM+ profiles made from EPS-F (expanded polystyrene) are one of the three system components of the TRIOTHERM+ system. The robust, hard-wearing profiles exhibit load-bearing capacity, can be fitted to the load-bearing structure quickly and easily, and offer thermally isolated load transfer – thermal bridges from the structurally necessary fastening of construction elements are reduced to a minimum. This prevents the risk of mould formation in the connection area around the window opening. TRIOTHERM+ profiles provide a high load-bearing capability and load transfer in one. The TRIOTHERM+ profiles can be integrated perfectly into the insulating zones of all façade systems. |

|

AREA OF APPLICATION |

| A major area of application of the TRIOTHERM+ profiles is for extending the masonry jamb in the insulation layer of the façade, as the load-bearing, dimensionally stable installation surface for the assembly parts to be fitted. The TRIOTHERM+ profiles can transfer the resulting forces reliably into the load-bearing structure via the mechanical fastening. The permanently dimensionally stable frame profiles always form a level plane for the regulation-compliant sealing of connecting joints between construction elements. |

SYSTEM ADHESIVE HYBRID POLYMER POWER FIX WHITEPOWER FIX is a neutral cure, single-component, permanently flexible adhesive on a hybrid-polymer basis. It is used especially for gluing the frame profiles and makes tension-free structural bonding of the system possible. POWER FIX is also used for sealing and bonding corner connections and can be used on damp surfaces. Refer to the Hybrid Polymer Power Fix white product data sheet for further information. |

| Adhesive Product Data Sheet |

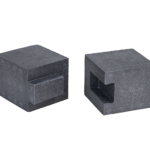

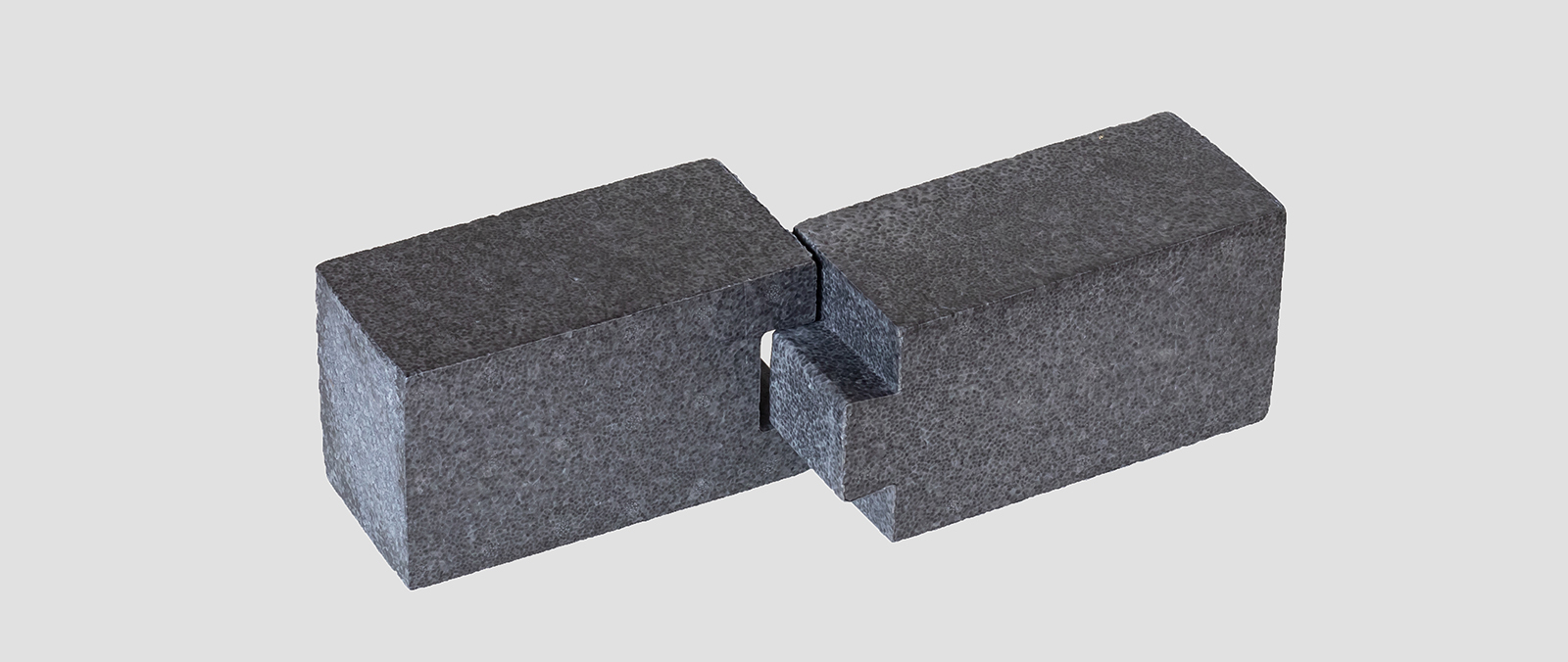

LENGTH ADJUSTMENTThe waste-free joining of the profiles brings clear advantages for the fitter. Thanks to their low weight and compact dimensions, the TRIOTHERM+ profiles are unbeatably quick and straightforward to process. Dovetail joint offer geometrical accuracy, very good fit at joint area and high level of stability. Expert sealing and mechanical fastening of the TRIOTHERM+ profiles to the load-bearing base is necessary, but takes only a few minutes. |

| Technical data | Standard | Classification |

| Triotherm+ | ||

| Material description | EPS-F | |

| Colour | grey | |

| Building material class | DIN EN 13501-1 | E |

| Bulk density | 150 kg/m³ ± 15% | |

| UV light stability | 12 months direct weathering during the construction phase | |

| Compatibility with adjacent building materials | compatible, except for solvents, solvent-bearing materials and materials that are not polystyrene-compatible | |

| Thermal conductivity | DIN EN 12667 | λ = 0,040 W/m*K |

| Form stability under thermal load | -40°C to +85°C | |

| Temperature stability range | ISO 75-1 | long term +85°C |

| Ageing resistance | mould-proof, non-rotting | |

| Bending resistance | DIN EN 12089 | ≥ 650 kPa |

| Shearing stress | DIN EN ISO 14130 | X = 0,217 N / mm² |

| Air permeability | EN 12207 | Class 4 |

| Compressive load bearing capacity at max. total deformation of 2% | 1,260 kg/dm² | |

| Screw withdrawal value: (Frame screw Fix FK-T30 7.5 x 62 mm) | 2100 N | |

| Water absorption (28 days storage) | DIN 12087 | ≤ 1.5 Vol. % |

| Water vapour diffusion resistance μ | DIN EN ISO 12572 | 380-550 |

| Waste code | 170604; 170904 | |

| Shelf life | 2 years |

| Type description | Length | Width | Height | Packing unit (pcs) |

| Triotherm+ profile 70×85 | 1175 mm | 70 mm | 85 mm | 9 |

| Triotherm+ profile 100×85 | 1175 mm | 100 mm | 85 mm | 6 |

| Triotherm+ profile 120×85 | 1175 mm | 120 mm | 85 mm | 6 |

| Triotherm+ profile 140×85 | 1175 mm | 140 mm | 85 mm | 6 |

| Triotherm+ profile 160×85 | 1175 mm | 160 mm | 85 mm | 6 |

| Triotherm+ profile 180×85 | 1175 mm | 180 mm | 85 mm | 3 |

| Triotherm+ profile 200×85 | 1175 mm | 160 mm | 85 mm | 3 |

| Triotherm+ profile 230×85 | 1175 mm | 180 mm | 85 mm | 2 |

| Product Data Sheet |

| Installation instruction |