ISO-CONNECT HB-BAND

|

|||||||

Product description |

Product advantages |

|

|

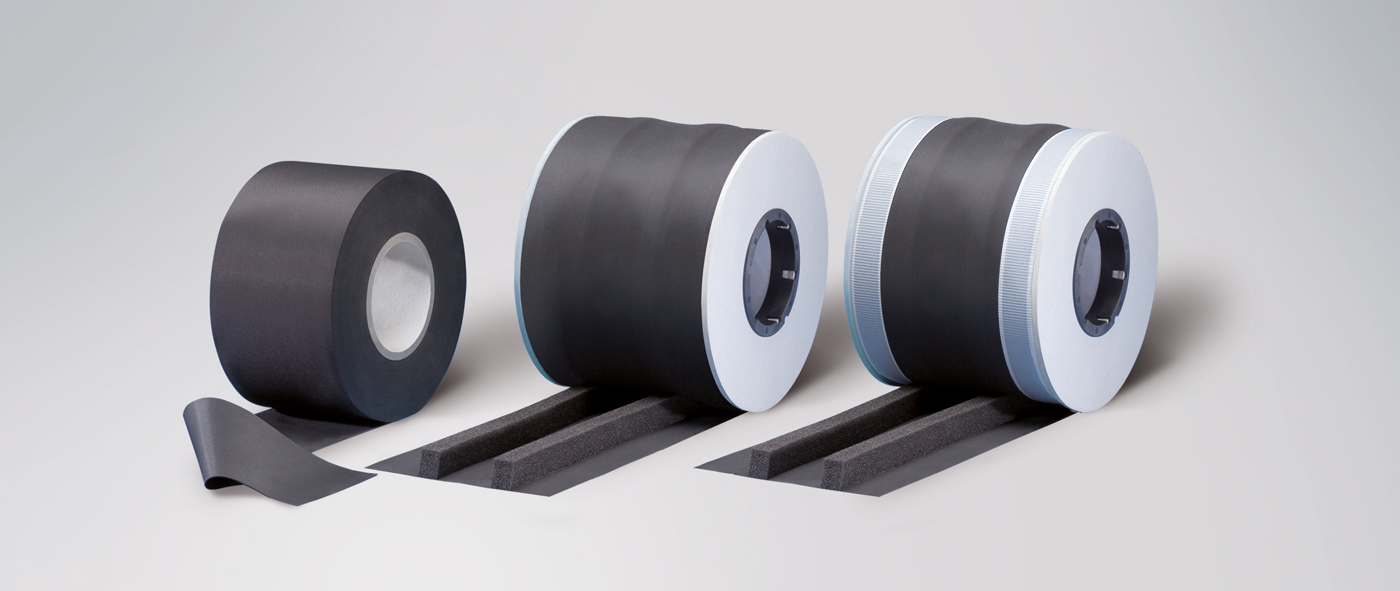

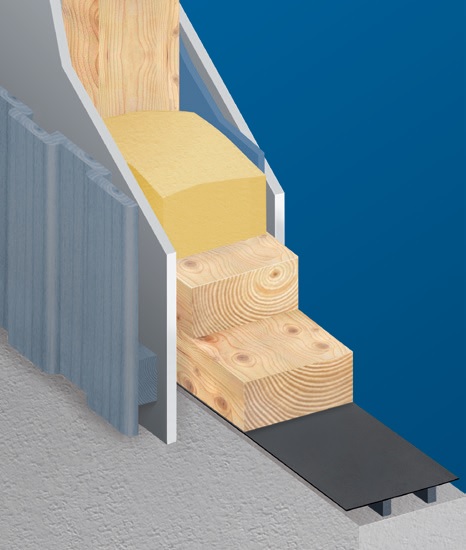

ISO-CONNECT HB-BAND is a highly pressure- esistant sealing strip that is primarily used in timber-framed buildings between the wall sole plate and foundation wall / floor slab as a capillary barrier. It is ideal for sealing against rising damp. It can be supplied ready prepared with:

|

|

|

Application |

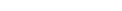

Finishes |

|

|

ISO-CONNECT HB-BAND is a specially-designed horizontal seal for timber-framed buildings. It prevents moisture migration from the supporting structure to the wall sole plate. With the addition of the impregnated foam strips, it also aids the air tightness and the thermal insulation between the two varying surfaces. |

|

|

Dimensions |

Packaging |

|

|

Thickness: 0.8 mm (plus impregnated tape, if added) Width: 120, 140, 150, 200, 250, 300, 400 mm (other dimensions available upon request) |

Rolls, roll length: 25 m. |

| Technical data | Standard | Classification |

| Material description | synthetic caoutchouc on EPDM basis | |

| Colour | black | |

| Building material class | DIN EN 13501 | E |

| UV – stability and ozone resistance | DIN 7864 T1 | requirements fulfilled |

| Air permeability coefficient of impregnated tapes | DIN EN 12114 | a ≤ 0,1 m³/[h*m*(daPa)ⁿ] |

| Water vapour diffusion resistance µ | DIN EB 1931 | 32000 |

| Tear growth resistance | DIN 53504 | ≥ 25 kN/m |

| Tensile strength | DIN 53504 | ≥ 6,5 Mpa |

| Elongation at break | DIN 53504 | ≥ 300% |

| Handling temperature | approximately +5°C to +35°C | |

| Temperature stability range | -30°C to +100°C | |

| Dimension tolerance | DIN 7715 TP P3 | requirements fulfilled |

| Thermal conductivity of impregnated tapes | DIN 52612 | λ ≤ 0,042 W/m*K |

| Shelf life and storage temperature | EPDM: unlimited, impregnated foam and butyl: 1 year at +1°C to +25°C |

Processing |

||

|

Preparation of the substrate The substrate must be clean, solid, dry and free of solvents. Using ISO-CONNECT HB-BAND Run the ISO-CONNECT HB-BAND along the length of either the sole plate, or the foundation wall. Ensure it is flat, but do not stretch, and fix it to the substrate.

If tapes are joined, allow an overlap of 20 cm. The ISO-CONNECT HB-BAND must protrude by roughly 1-2 cm on both sides to prevent damp bridges occurring on either side of the wall. The overlaps can be bonded with ISO-TOP FLEX-ADHESIVE XP. |

Installation example |

|

|

| Product Data Sheet |