Preparation

|

|

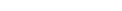

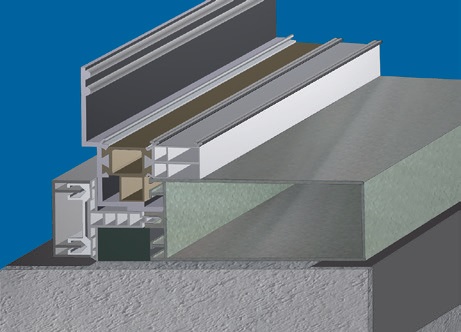

| Installation example |

|

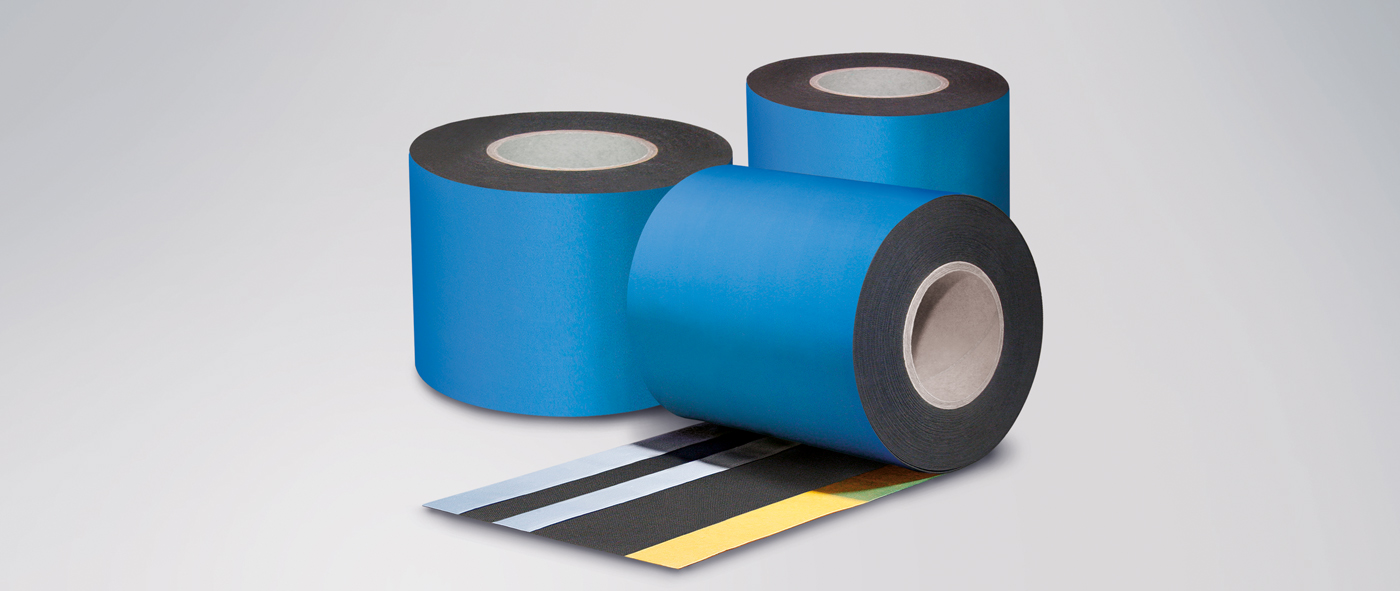

Dimensions

|

| Width: 100, 150, 200, 250, 300, 400, 500 mm

(other dimensions available upon request) |

Packaging

|

| Rolls, roll length: 25 m |

|

|

Unroll ISO-CONNECT INSIDE EPDM sealing band and cut to the required length. The surface must be clean, dry and free from solvents, grease, dust and other anti-adhesive substances.

|

|

|

Generating an air-tight joint with the means of partial surface adhesion using gunable, paste-like and solvent free adhesive (ISO-TOP FLEX-ADHESIVE XP). Primer is not necessary with ISO-TOP FLEX-ADHESIVE XP, with the correct professional preparation. An additional mechanical fixing e. g. clamps and the securing on the window is to be applied as described in DIN 18195.

Alternatively, versions B and D are supplied with an acrylic adhesive strip to assist attaching the end to the aluminium window until the mechanical fixings are installed, or a gunned adhesive is applied. When using versions with Butyl adhesive, pre-treat any porous and absorbent surfaces with a suitable primer (ISO-TOP BLUE PRIMER) and then apply the self-adhesive material to the surface. For all adhesive areas use a roller to carefully apply pressure to the area until the product adopts the contours of the facade.

Butyl caoutchouc adhesives are sensitive to solvents. On complete surface bonding using solvent based contact adhesive, coat both the band and the surface and then carefully press into place.

|

|