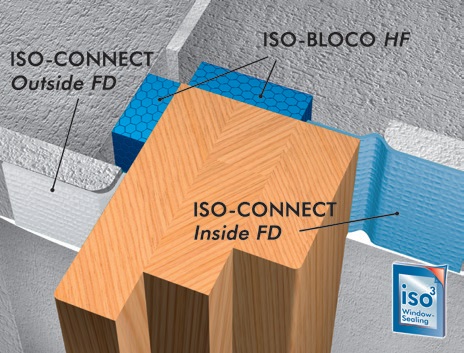

ISO-CONNECT INSIDE FD

Product description |

Product advantages |

||

|

ISO-CONNECT INSIDE FD is an extremely flexible and stretchable special foil for an air and wind tight sealing on window, door, and panel connecting joints. ISO-CONNECT INSIDE FD consists of a flexible soft synthetic fleece, which is equipped with a self-adhesive strip on one edge for easy and effective application on window and door frames. The water vapour diffusion impereable fleece membrane provides a reliable separation between internal and external conditions and complies with the requirements of the energy saving regulation (EnEV) as well as the RAL installation guidlines. |

|

||

Applications |

|||

Service |

|||

| ISO-CONNECT INSIDE FD is a component of the ISO³-WINDOW SEALING SYSTEM and is used to seal internal window and door connecting joints. The special versatile foil is very flexible in its application and is characterised through its low inherent rigidity, allowing problem-free application around corners and conforms to different shapes. Due to the extremely high elasticity of the material it is particularly suitable for the reliable sealing of moving joints. Even on extreme movements between elements the flexible widow connecting film ensures a high ultimate tensile strength. |

|

| Technical data | Standard | Classification |

| Material description | vapour diffusion impermeable synthetic fleece | |

| Colour | blue | |

| Weight | approximately 180 g/m² | |

| Impermeable to driving rain | DIN EN 1027 | ≥ 1050 Pa |

| Air permeability coefficient | DIN EN 12114 | a ≤ 0,1 m³/[h*m*(daPa)ⁿ] |

| UV light stability | approximately 3 months | |

| Temperature stability range | internal | -40°C to +80°C |

| sd-value | DIN EN ISO 12572 | approximately 39 m |

| Flexibility at -23°C | internal | no breaks, no tears |

| Fire behaviour | DIN 13501 | E |

| Dimension tolerance | DIN 7715 T5 P3 | requirements fulfilled |

| Shelf life | 1 year, dry and in original packing | |

| Storage temperature | +1°C to +20°C |

Processing |

Finishes |

|

| The bonding surfaces must be firm, dry, clean from dust, stripping agents, solvents, oil and grease. When sealing window, panel and door frame connections remove backing from the self-adhesive strip, then lay the foil into position and press firmly. ISO-CONNECT INSIDE FD can be applied in the factory or workshop. For bonding to walls ISO-TOP FLEX-ADHESIVE SP or SP+ is used. Normal rough, e.g. uneven wall surfaces, can be compensated for through the application of a sufficent amount of adhesive. Use sufficient adhesive so that after applying the foil the adhesive caterpillar is at least 30 mm wide and 1 mm thick. On areas that are to be plastered over a continuous „Z“ shaped caterpillar should be applied over the area. Fully self-adhesive finish COMPLETE and COMPLETE DUO does not require any additional adhesion with our ISO-TOP FLEX ADHESIVE. Overlapping of the foil ends should only be up to 50 mm wide using the same technique. Plastering over can be done as soon as the adhesive bond is enough to carry the weight of the plaster. |

Finish SK: single side self-adhesive with 1 self-adhesive strip. Finish COMPLETE: full surface adhesive finish with a 2-way or 3-way split liner. Finish COMPLETE DUO: full surface adhesive finish with a 2-way or 3-way split liner and 1 self-adhesive strip (window mounting). Special finishes available on request. |

|

Dimensions |

||

| width finish SK: 70, 90, 145, 180, 235, 290 mm width finish COMPLETE: 70, 100, 140, 200 mm width finish COMPLETE DUO: 70, 100, 140 mm | ||

Packaging |

||

| Rolls, roll length: 30 m. | ||

|

|

|

| Product Data Sheet |