PRODUCT DESCRIPTION

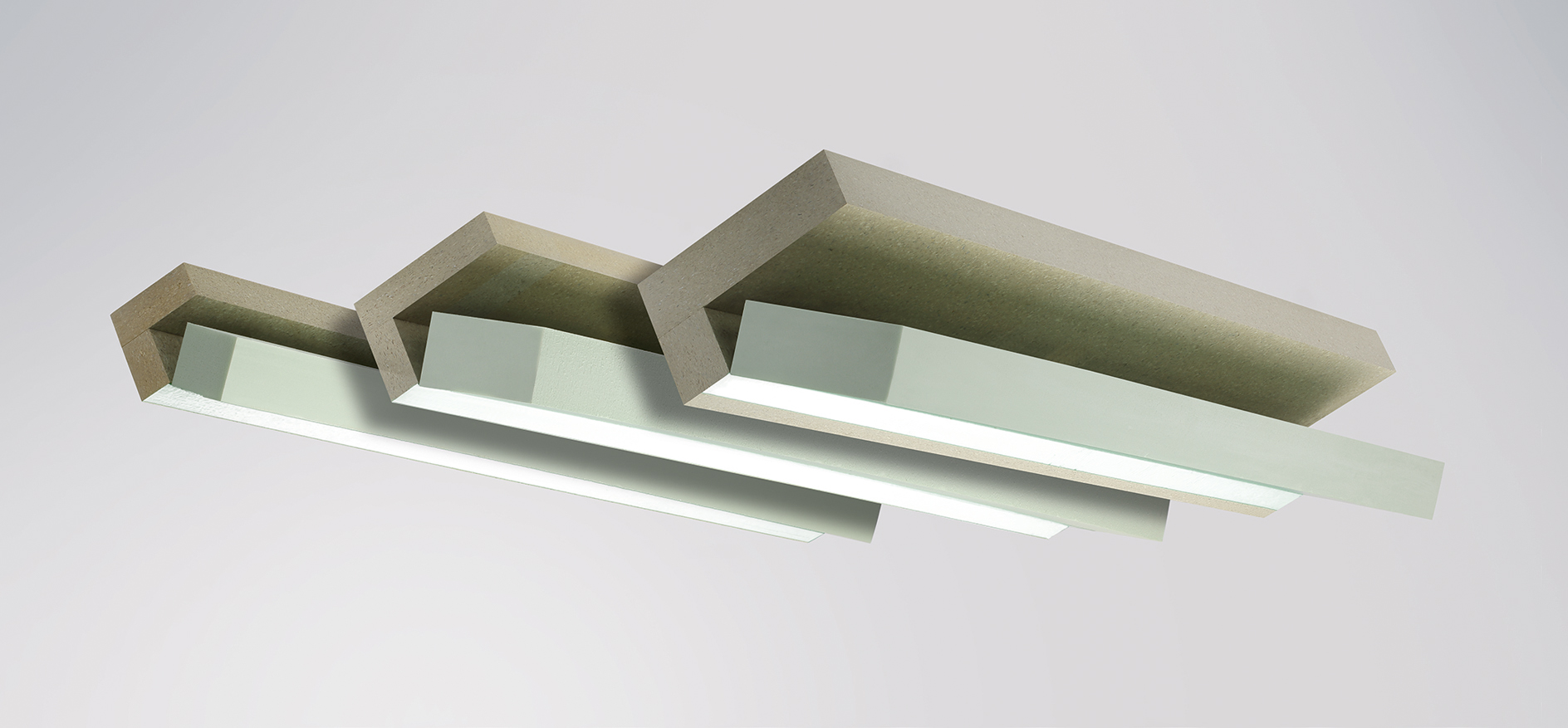

The IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER „TYPE 1“ makes it possible to position and fit windows within the insulation plane. The IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER „TYPE 1“ comprises a thermally insulating and load-bearing system angle made of PURATHERM which is equipped with a highly thermally insulating core. The thermally insulating core is connected to the system angle by means of a hinged mechanism. The advantage of this is that the insulating core can simply be moved out of the way while mechanically securing with screws.

System boards are also available for applications where the window is only partially overhanging. In addition, the system brackets can be combined with the system boards to achieve greater overhangs. ISO-TOP WINFRAMER SYSTEM BRACKETS „TYPE 1“ and SYSTEM BOARDS are prefabricated in many different formats and can be cut to length on site using a mitre saw. Attachment to the masonry is by means of ISO-TOP FLEX-ADHESIVE WF and additional attachment using screws (not included in the range).

PRODUCT ADVANTAGES

- windows can be fitted into the outer thermal insulation level

- integrated thermal insulation core (system brackets)

- simple adjustment of length using standard mitre saws

- reduction of structure-related thermal bridges

- simple installation thanks to the convenient insertion system

- certified Passive House component phB

- complies with EnEV requirements and the recommendations of the RAL “installation guide”

- can be combined with the system products of the ISO3-WINDOW SEALING SYSTEM

- Can be plastered over directly

- can be combined with the IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER „TYPE 2“

- 10 year performance guarantee*

*On the conditions of the manufacturer (available upon request).

Applications

The system brackets and boards are suitable for bearing the loads of windows and doors and provide an optimum base for sealing window connection joints. The window and door elements are attached directly and mechanically to the supporting frame system. This is possible with both classic screw fixings trough the window frame, or with extended metal lug fixings.

SYSTEM COMPONENTS

The in front of wall installation system is then covered by either an External Wall Insulation system, or rain screen facade of whatever type is designed. The integrated thermal core of the system together with the solid installation frame guarantee an optimum Ψ-value (Psi).

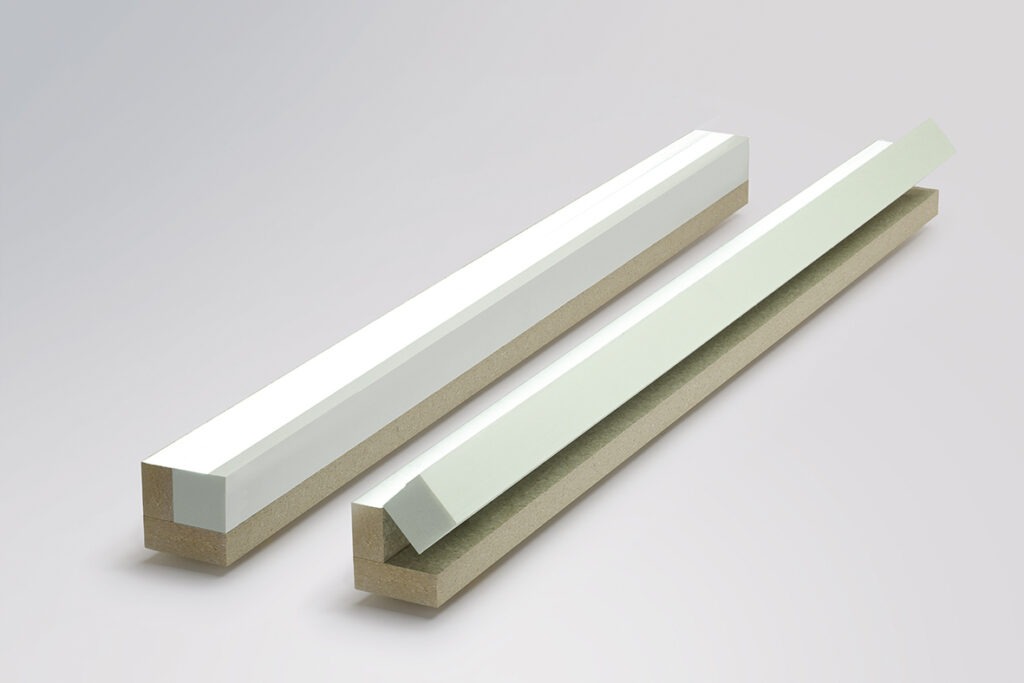

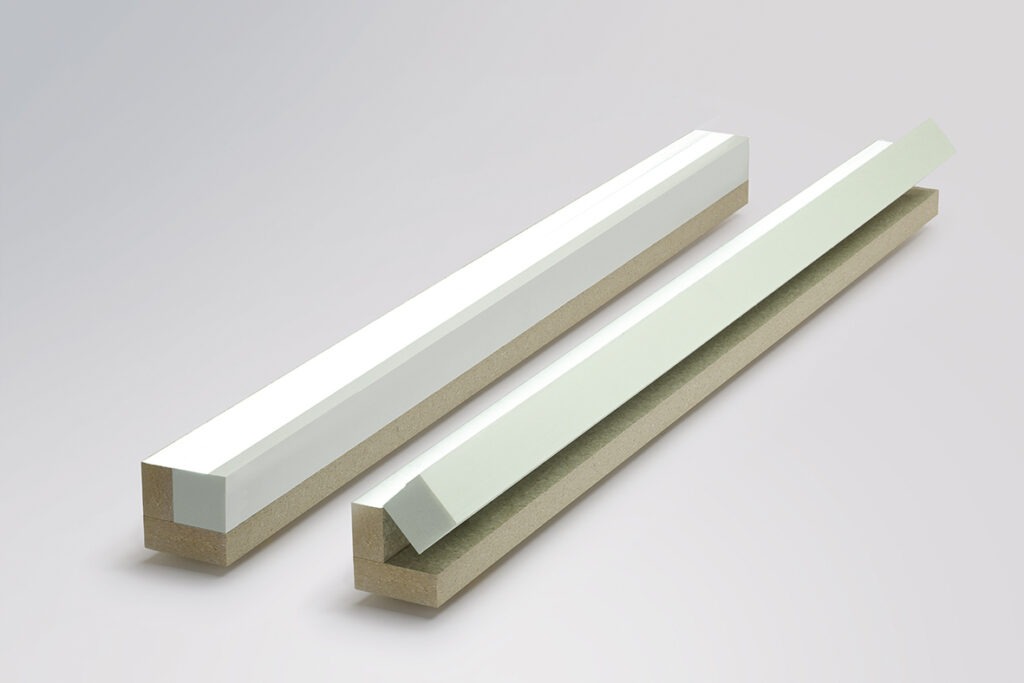

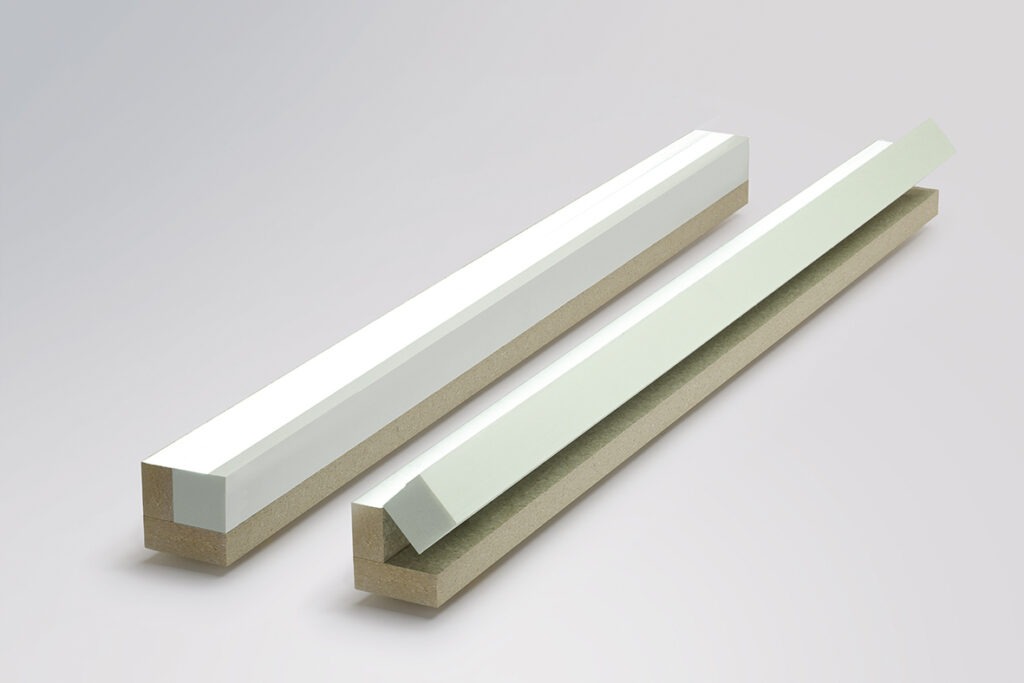

ISO-TOP WINFRAMER SYSTEM BRACKET "TYPE 1" 80 / 80, 90 / 80

The system bracket 80 / 80 resp. 90 / 80 is available for typical in front of wall installations. The ISO-TOP WINFRAMER SYSTEM BRACKETS „TYPE 1“ 80 / 80 resp. 90 / 80 are suitable whenever windows are fitted in the direct transition area between the wall and the External Wall Installation system. With its 80 mm resp. 90 mm width dimension it has been adapted to standard window systems. The fixing areas guarantee a straightforward, fast and reliable window installation.

ISO-TOP WINFRAMER SYSTEM BRACKET "TYPE 1" 120 / 90; 140 / 90

With an extension of 40 mm and 60 mm, the ISO-TOP WINFRAMER SYSTEM BRACKET „TYPE 1“ 120 / 90 and 140 / 90 are designed for deeper window profiles, or for use with combination products such as roller shutters etc. These additional products can be fitted within the depth of the ISO-TOP WINFRAMER SYSTEM BRACKET „TYPE 1“ so the perimeter seals are all at the same plane. The sealing can be done within the system bracket level, as planned.

ISO-TOP WINFRAMER SYSTEM BRACKET "TYPE 1" 160 / 110, 180 / 110, 200 / 110

The ISO-TOP WINFRAMER SYSTEM BRACKETS „TYPE 1“ with a maximum projection of 200 mm can be used for cavity wall structures with brick facades. This system component is available for especially large projections of 160, 180 and 200 mm. Thermal insulating layers are becoming thicker not only where External Wall Insulation (EWI) systems are used, but also on buildings with assorted rainscreen facades, such as brick, etc. As with the EWI finish the ISO-TOP WINFRAMER SYSTEM BRACKET „TYPE 1“ should be attached to the front of the load bearing wall.

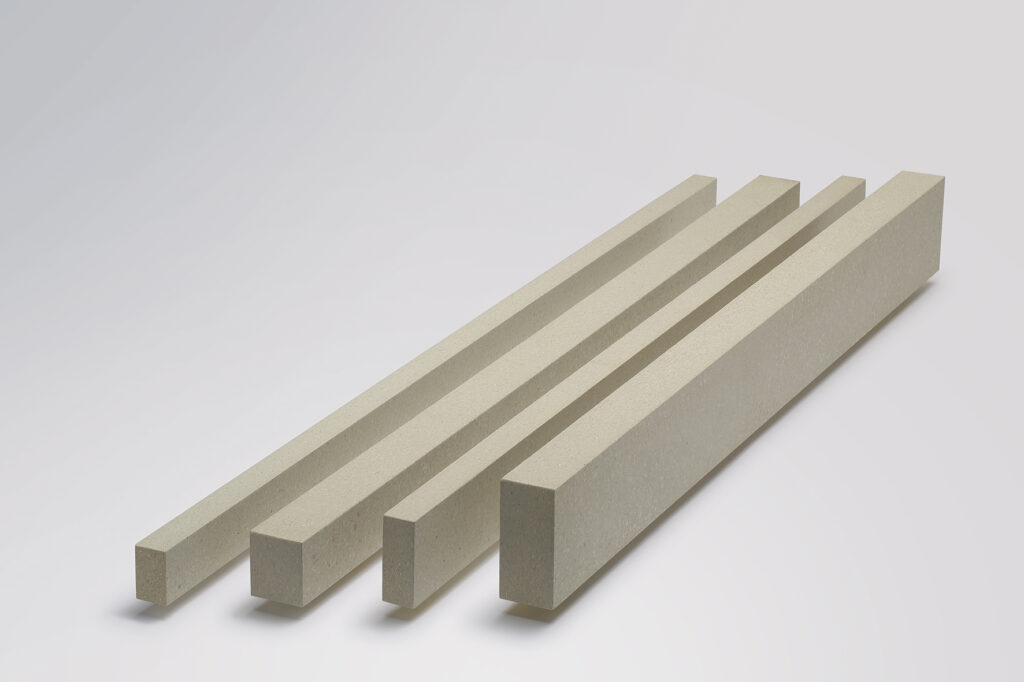

ISO-TOP WINFRAMER SYSTEM BOARDS

The system boards in the IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER „TYPE 1“ offer a range of different application options. ISO-TOP WINFRAMER SYSTEM BOARDS are also available for applications where the window is only partially overhanging with some External Wall Insulation systems. In addition, the system brackets can be combined with the system boards to achieve greater overhang.

SYSTEM ADHESIVE ISO-TOP FLEX-ADHESIVE WF

ISO-TOP FLEX-ADHESIVE WF is a high-quality, neutral cure, single-component, permanently flexible adhesive on a hybrid-polymer basis. It was developed especially for gluing the IN FRONT OF WALL INSTALLATION SYSTEMs ISO-TOP WINFRAMER and makes tension-free structural bonding of the system possible. ISO-TOP FLEX-ADHESIVE WF is also used for sealing and bonding corner connections and can be used on damp surfaces. Refer to the ISO-TOP FLEX-ADHESIVE WF product data sheet for further information.

PROCESSING

The IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER „TYPE 1“ is sealed to the masonry using ISO-TOP FLEX-ADHESIVE WF. This can also be used for optimum sealing of the material joints and corners.The use of further ISO3-WINDOW SEALING SYSTEM products is recommended for seals between the window and the in front of wall installation system. More detailed processing information can be found in the installation instructions.

ISO-TOP WINFRAMER INSERTION SYSTEM

ISO-TOP WINFRAMER SYSTEM BRACKETS „TYPE 1“ are equipped with a convenient insertion system as standard. The tongue and groove design allows the ends of system brackets to be fitted together easily and quickly. System joints are glued using ISO-TOP FLEX-ADHESIVE WF. The practical insertion system makes installation significantly easier on long rows of windows, allowing work to be mastered professionally by a single person. In addition, the insertion system makes levelling of the system brackets to be installed easier, enhancing the attractive appearance and technical installation quality.

| Technical data | Standard | Classification |

| ISO-TOP WINFRAMER SYSTEM BRACKETS “TYPE 1” and SYSTEM BOARDS | ||

| Material description | PUR composite | |

| Colour | beige | |

| Building material class | DIN EN 13501-1 | E |

| Building material approval | Z-23.11-2014 | |

| Fire resistance period | EN 1366-4 | EI 15 |

| Thermal conductivity | DIN EN 12667 | λ = 0,096 W/m*K |

| Average U-value: finish 80 / 80 | U = 0,51 W/m2*K; | |

| Average U-value: finish 140 / 90 | U = 0,27 W/m2*K; | |

| Average U-value: finish 200 / 110 | U = 0,2 W/m2*K | |

| Sound reduction | depending on the sound insulation class of the construction element / window up to 50 dBA in the joint | |

| Temperature stability range | -50°C to i +100°C | |

| Ageing resistance | resistant to rotting, non-rotting | |

| Humidity resistance | high humidity resistance / resistant to mould and termites | |

| Dimensional stability | high dimensional stability even with natural weathering | |

| Load transfer | 200 kg/m depending on wall substrate and projection* | |

| Dimension tolerance | DIN 7715 T5 P3 | requirements fulfilled |

| Shelf life (system brackets, system boards and insulating core) | 2 years |

| Technical data: insulating core | Standard | Classification |

| Material description | XPS | |

| Building material class | DIN 4102 | B1 |

| Thermal conductivity | DIN EN 12667 | λ = 0,034 W/m*K |

| Resistance | usual construction materials, except solvents | |

| Dimension tolerance | DIN 7715 T5 P3 | requirements fulfilled |

DELIVERY RANGE

| Type description | Length | Width | Height | Load transfer |

| ISO-TOP WINFRAMER SYSTEM BRACKET “TYPE 1” 80/80 | 1200 mm | 80 mm | 80 mm | 200 kg/m |

| ISO-TOP WINFRAMER SYSTEM BRACKET “TYPE 1” 90/80 | 1200 mm | 90 mm | 80 mm | 200 kg/m |

| ISO-TOP WINFRAMER SYSTEM BRACKET “TYPE 1” 120/90 | 1200 mm | 120 mm | 90 mm | 200 kg/m |

| ISO-TOP WINFRAMER SYSTEM BRACKET “TYPE 1” 140/90 | 1200 mm | 140 mm | 90 mm | 200 kg/m |

| ISO-TOP WINFRAMER SYSTEM BRACKET “TYPE 1” 160/110 | 1200 mm | 160 mm | 110 mm | 200 kg/m |

| ISO-TOP WINFRAMER SYSTEM BRACKET “TYPE 1” 180/110 | 1200 mm | 180 mm | 110 mm | 200 kg/m |

| ISO-TOP WINFRAMER SYSTEM BRACKET “TYPE 1” 200/110 | 1200 mm | 200 mm | 110 mm | 200 kg/m |

| ISO-TOP WINFRAMER SYSTEM BOARDS | 1200 mm | width/height: 30/50; 30/60; 30/80; 30/90; 50/60; 50/80; 50/110 mm | ||

| ISO-TOP FLEX-ADHESIVE WF | for fixing on the wall and sealing the system joints | |||

Details and information presented in this document are based on the best knowledge available at the time. They are intended for general information purposes, and it is recommended that users conduct their own tests under their specific conditions to ensure the product’s suitability for its intended use. No definitive guarantee or liability can be given regarding the details or the absolute completeness of the information provided in these guidelines. We reserve the right to improve or modify technical specifications and information without prior notice.