PRODUCT DESCRIPTION

ISO-TOP WINFRAMER „TYPE 1“ PREFAB is the project-related version of the supporting frame „TYPE 1“ in front of wall installation system prefabricated at the factory to optimise time and costs. The main advantages are its configurable delivery lengths as well as the option of prefabricating complete supporting frames. In addition, the „TYPE 1“ PREFAB has all the technical advantages of the tried-and-trusted „TYPE 1“.

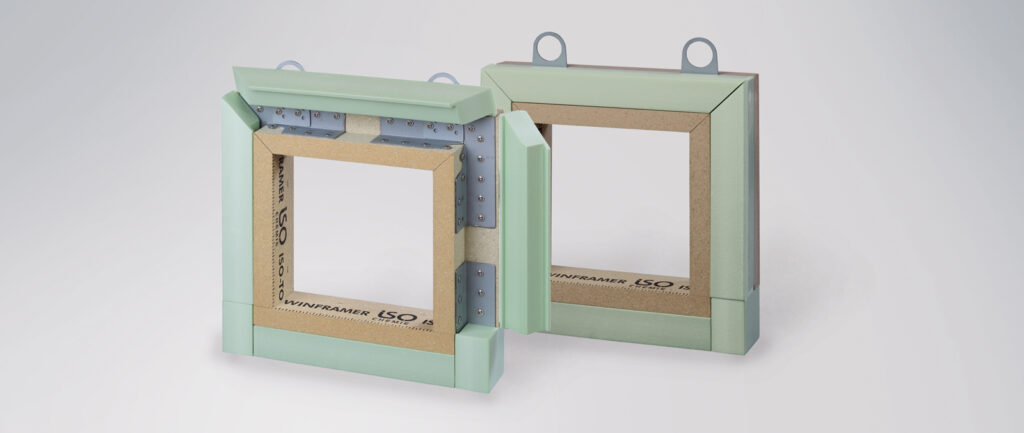

The system brackets of the IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER „TYPE 1“ PREFAB can be produced individually according to the object-specific lengths required. Delivery in tailor-made project lengths makes it possible to prefabricate complete supporting frames for different window openings in your factory. This means corresponding window frames can be pre-assembled with a RAL-compliant sealing system in the prefabricated supporting frame of the IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER „TYPE 1“ PREFAB.

There are several advantages to prefabrication. Workflows in your factory can be optimised in terms of time and costs under controlled conditions. This saves money and makes costing calculations more reliable. Assembly in the factory – no matter the weather conditions outside – prevents any problematic assembly delays. Furthermore, assembly times on the construction site can be significantly reduced.

Applications

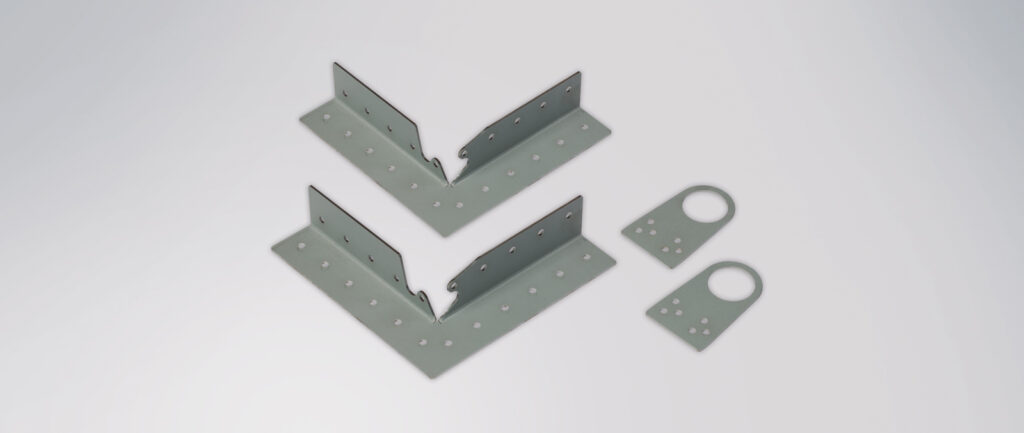

The IN FRONT OF WALL INSTALLATION SYSTEM ISO-TOP WINFRAMER „TYPE 1“ PREFAB can be used for the complete in front of wall installation with a window element as a closed frame system. The four individual parts of the frame are delivered with a building-specific cut length of up to 3,600 mm and mechanically connected using specially developed ISO-TOP WINFRAMER CORNER CONSOLES made of metal. Optionally available ISO-TOP WINFRAMER CRANE EYELETS allow ready-to-assemble facade elements comprising a supporting frame element and window frame to be transported to the installation location and lifted to the respective installation spot by crane.

SYSTEM COMPONENTS

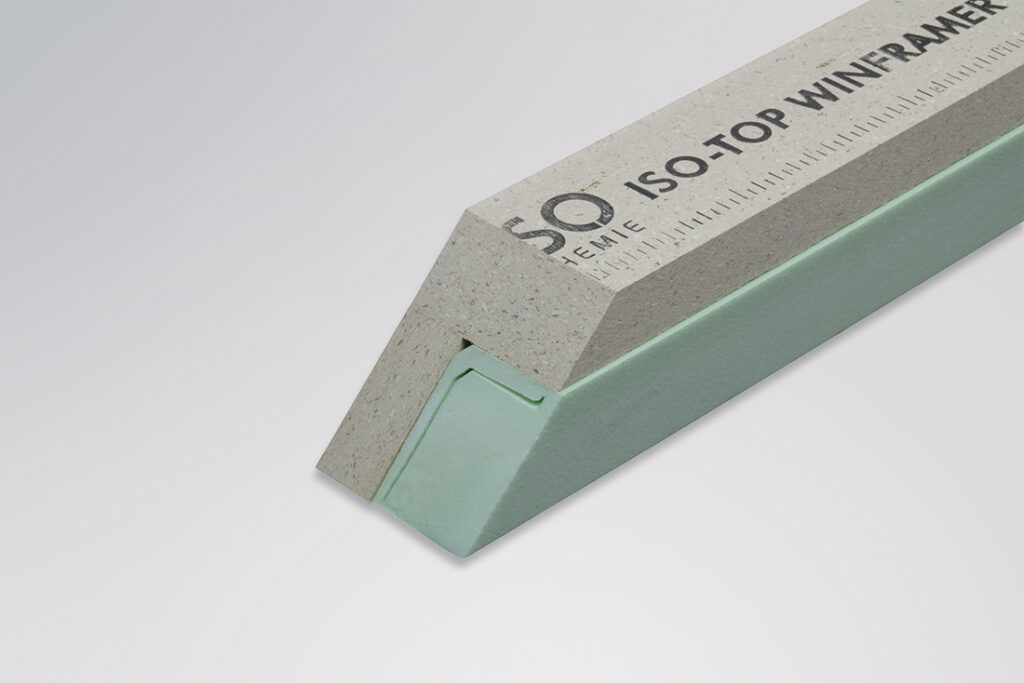

The „TYPE 1“ PREFAB is glued to the outside masonry all the way round the window opening first using the system adhesive ISO-TOP FLEX-ADHESIVE WF and then screwed in place. The requirement of using ETA-tested attachment systems to match the outside masonry and the edge projection specifications applies here too. Subsequently, a segment of the movable insulating core is partially broken out via a pre-designed break-off line to positively fit the corner consoles and then fixed using a few adhesive points. The insulating core guarantees reliable integration in the EWIS by reducing thermal bridges.

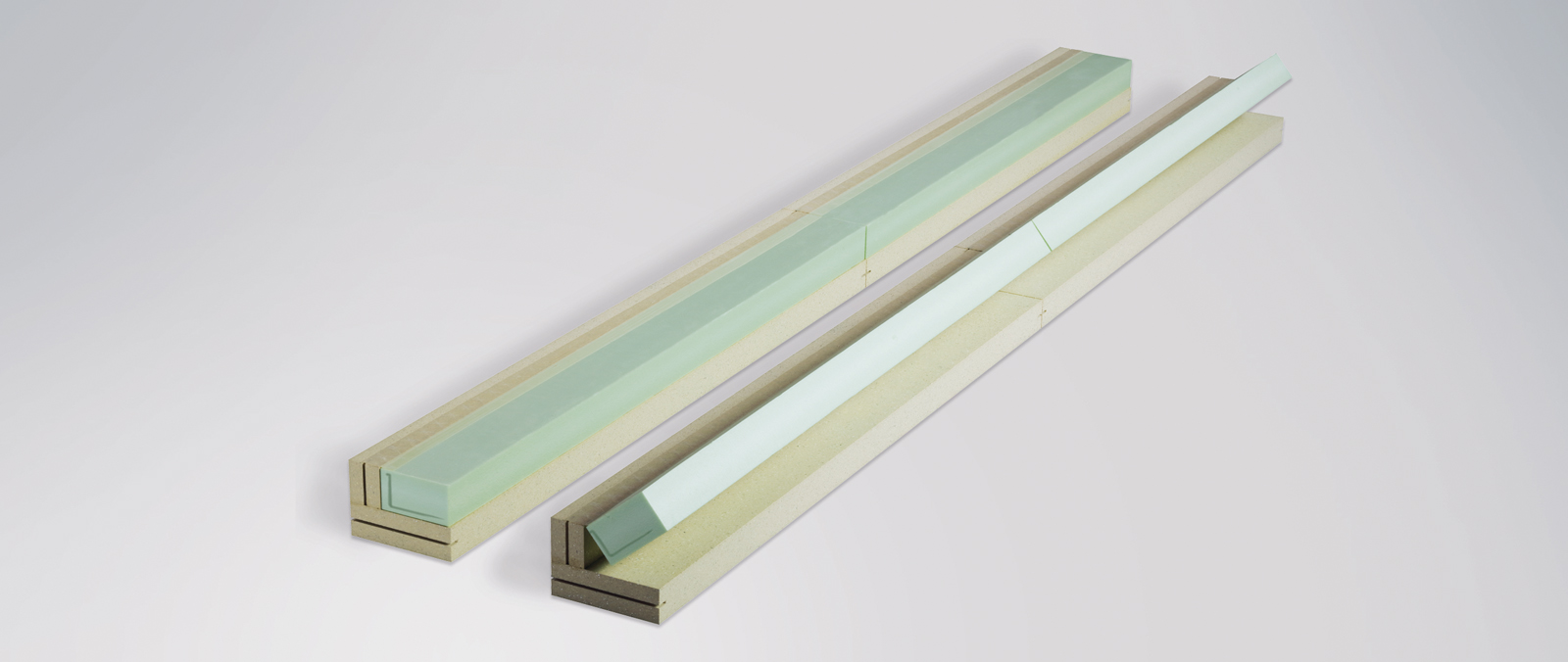

ISO-TOP WINFRAMER SYSTEM BRACKETS „TYPE 1“ PREFAB 80 / 80 - 200 / 110

We have ISO-TOP WINFRAMER SYSTEM BRACKETS „TYPE 1“ PREFAB in the dimensions 80 / 80, 90 / 80, 120 / 90, 140 / 90, 160 / 110, 180 / 110 and 200 / 110 in the range for typical in front of wall installation applications. Since most building projects have differently dimensioned window openings, we provide the system brackets for „TYPE 1“ PREFAB in individual cut lengths up to 3,600 mm. This avoids residue on site and makes expensive adaptation unnecessary. The ISO-TOP WINFRAMER CORNER CONSOLES screwed into the rebate area are covered with the ISO-TOP WINFRAMER INSULATING CORE „TYPE 1“ PREFAB to reduce structural thermal bridges.

ISO-TOP WINFRAMER INSULATING BLOCKS

The corners of the 4-sided frame system can be mitre-cut or butt-jointed. The prefabricated ISO-TOP WINFRAMER INSULATING BLOCKS can be used for thermal insulation at butt-jointed corners. They are available as an option for the standard dimensions.

ISO-TOP WINFRAMER CORNER CONSOLES & CRANE EYELETS

We supply specially developed corner consoles made of metal for the connection of the four ISO-TOP WINFRAMER SYSTEM BRACKETS „TYPE 1“ PREFAB to a prefabricated supporting frame. The ISO-TOP WINFRAMER CORNER CONSOLES are screwed in the rebate area and then covered with the movable insulating core. The optional ISO-TOP WINFRAMER CRANE EYELETS allow the ready to assemble facade element made up of a supporting frame and window frame to be transported by crane to the respective installation spot.

| Technical data | Standard | Classification |

| ISO-TOP WINFRAMER SYSTEM BRACKETS “TYPE1”, “TYPE 1” PREFAB and SYSTEM BOARDS | ||

| Material description | PUR composite | |

| Colour | beige | |

| Building material class | DIN EN 13501-1 | E |

| Building material approval | Z-23.11-2014 | |

| Thermal conductivity | DIN EN 12667 | λ = 0,096 W/m*K |

| Average U-value: finish 80 / 80 | U = 0,51 W/m2*K; | |

| Average U-value: finish 140 / 90 | U = 0,27 W/m2*K; | |

| Average U-value: finish 200 / 110 | U = 0,2 W/m2*K | |

| Sound reduction | depending on the sound insulation class of the construction element / window up to 50 dBA in the joint | |

| Temperature stability range | -50°C to i +100°C | |

| Ageing resistance | resistant to rotting, non-rotting | |

| Humidity resistance | high humidity resistance / resistant to mould and termites | |

| Dimensional stability | high dimensional stability even with natural weathering | |

| Load transfer | 200 kg/m depending on wall substrate and projection* | |

| Shelf life (system brackets, system boards and insulating core) | 2 years |

| Technical data: insulating core | Standard | Classification |

| Material description | XPS | |

| Building material class | DIN 4102 | B1 |

| Thermal conductivity | DIN EN 12667 | λ = 0,034 W/m*K |

| Resistance | usual construction materials, except solvents |

| *Our STATIC-TOOL is available for detailed preliminary dimensioning. |

DELIVERY RANGE

| Type description | Length | Width | Height | Load transfer |

| ISO-TOP WINFRAMER SYSTEM BRACKET “TYPE 1” PREFAB 80/80 | 3600 mm | 80 mm | 80 mm | 200 kg/m |

| ISO-TOP WINFRAMER SYSTEM BRACKET “TYPE 1” PREFAB 90/80 | 3600 mm | 90 mm | 80 mm | 200 kg/m |

| ISO-TOP WINFRAMER SYSTEM BRACKET “TYPE 1” PREFAB 120/90 | 3600 mm | 120 mm | 90 mm | 200 kg/m |

| ISO-TOP WINFRAMER SYSTEM BRACKET “TYPE 1” PREFAB 140/90 | 3600 mm | 140 mm | 90 mm | 200 kg/m |

| ISO-TOP WINFRAMER SYSTEM BRACKET “TYPE 1” PREFAB 160/110 | 3600 mm | 160 mm | 110 mm | 200 kg/m |

| ISO-TOP WINFRAMER SYSTEM BRACKET “TYPE 1” PREFAB 180/110 | 3600 mm | 180 mm | 110 mm | 200 kg/m |

| ISO-TOP WINFRAMER SYSTEM BRACKET “TYPE 1” PREFAB 200/110 | 3600 mm | 200 mm | 110 mm | 200 kg/m |

| ISO-TOP WINFRAMER INSULATING BLOCKS | width/height: 80/80; 90/80; 140/90; 160/110; 180/110 and 200/110 mm; length 50 mm (80/80; 90/80) and 60 mm (140/90; 160/110; 180/110; 200/110) | |||

| ISO-TOP FLEX-ADHESIVE WF | for fixing on the wall and sealing the system joints | |||

Details and information presented in this document are based on the best knowledge available at the time. They are intended for general information purposes, and it is recommended that users conduct their own tests under their specific conditions to ensure the product’s suitability for its intended use. No definitive guarantee or liability can be given regarding the details or the absolute completeness of the information provided in these guidelines. We reserve the right to improve or modify technical specifications and information without prior notice.